SCP Case Study: Kingsport, Tennessee Salt Sheds

The City of Kingsport, Tennessee has been curing their

sidewalks and exterior concrete projects with SCP

Technology for many years. For one of their new salt

sheds, the city wanted to use the entrance slab as a

means to evaluate the effectiveness of various SCP

Technology options against corrosive salt attack. They

wanted to see what an integral use of SCP products

would provide in comparison to their current P3 Protect

use, compared to their past use of ASTM C309 curing.

The SCP treated sections, integral and spray-treated,

would be placed side-by-side with standard concrete in

order to have a true comparison.

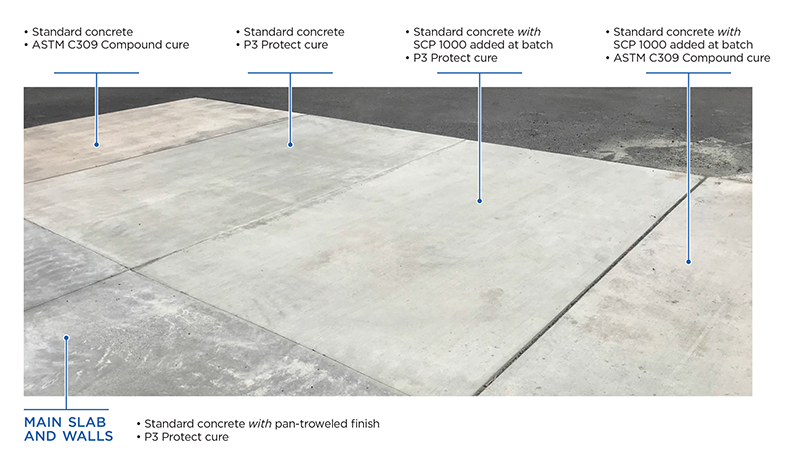

The main slab and storage walls of the salt shed were

cured with P3 Protect, as is the standard for city

concrete. For the evaluations, the entrance slab was

divided with construction joints into four equal sections,

with one load of concrete pouring two sections, each

receiving different curing products, allowing for four

variation panels. The same base concrete mix design

was used for the entire placement. The difference in

the four panels is demonstrated in the

photograph below. Salt was loaded

into the structure less than 60 days

after construction and treatment of

the storage slab and walls..

The main slab and storage walls of the salt shed were

cured with P3 Protect, as is the standard for city

concrete. For the evaluations, the entrance slab was

divided with construction joints into four equal sections,

with one load of concrete pouring two sections, each

receiving different curing products, allowing for four

variation panels. The same base concrete mix design

was used for the entire placement. The difference in

the four panels is demonstrated in the

photograph below. Salt was loaded

into the structure less than 60 days

after construction and treatment of

the storage slab and walls..

After only one season of use,

and less than 9 months after

construction, the difference in surface

appearance is strikingly clear. As one

city official put it, “Right there you can see

the difference in the concrete. Whatever the tests show,

that visible difference right there is the reason why we

use SCP for curing our concrete. It just makes it better.”

SCP and the city continue to make regularly scheduled

visits to the project to conduct both visual observations

and surface resistivity readings in order to compare the

long-term effects in this highly aggressive environment.